ACOME Compact Tube® – Technology with multiple benefits

Optical fibre is made of glass, and as such, it is the sensitive component in superfast networks which must be protected by the cable.

Cables for access networks, such as FTTH, have an additional challenge on top of this: access to individual fibres grouped by module. The compact tube technology has been specially developed to meet this need.

ACOME Compact Tube® technology improves most installation phases by focusing on speed, quality and secure access to the fibre. Find out why this is the case, in comparison to standard technologies such as Loose Tube or Micro-Loose Tube.

ACOME Compact Tube® vs Loose Tube and Micro Loose Tube

Fast and secure access to the fibre

While accessing the fibre in a Loose Tube (or micro-tube) requires specific tools (and comes with the risk, however small, of damaging the fibre), the development of ACOME Compact Tube® allows for "tool-free” work that is cleaner: the protective sheath can be removed with just two fingers.

In addition, this operation is particularly clean as it does not generate any microparticles, and it requires much less cleaning time than when using Loose Tube technology. The latter contains a larger amount of jelly which makes the work area dirty and therefore requires cleaning, which then increases preparation time.

| Compact Tube® | Loose Tube | |

| 1 | ||

| 2 |

Optimised tube and fibre management

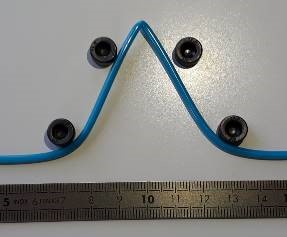

Better resistance to bending

The tubes are used for grouping, and they also serve to protect bare fibres. They must be handled carefully so as not to damage the fibres. When a tube is wound around itself below a certain bending radius, it collapses in on itself instantly and irreversibly, creating a sharp angle. This is the well-known kink effect (see photo below). When this point is reached, at best, the fibres are under stress, and at worst, all or part of the fibres inside the tube are broken. ACOME Compact Tube® technology allows for very low bending radius and eliminates the kink effect.

| Compact Tube® | Loose Tube |

|

No kink effect |

Kink effect |

Saves times and increases efficiency in preparing and assembling tubes

Unlike Loose Tube, ACOME Compact Tube® technology is not subject to any shape memory: management is therefore much simpler in confined spaces (distributors, racks or modules). Preparation time and results are optimised.

Easy access in boxes and organisers

The Compact Tube® offers a much easier way to access all the cable tubes. The images below show that Compact Tube technology allows six times more fibres to be accommodated than Loose Tube in a box of the same size.

| 864fo Compact Tube® | 144fo Loose Tube |

|

|

Reduction in diameter and weight of fibre optic cable

Size and weight are key characteristics of the cable. Whether overhead or underground, weight and diameter are closely linked to performance as regards:

- Maximum range

- Subsidence

- Pulling

- Jetting

- Resistance to weather hazards (wind speed, snow, ice)

The latest developments in the market show that the diameter of the Compact Tube is more than 40% smaller than the Loose Tube and 5% smaller than the Micro Loose Tube. Given that the Compact Tubes are smaller, while still accommodating an equivalent quantity of fibres, the diameter of the cable will be reduced, and therefore its weight as well.

Cables in ducts

The outside diameter of the cable must be assessed in relation to the inside diameter of the duct into which it must be pulled or jetted. Reducing the size of the cable also reduces the contact surface between the cable and the duct, which reduces friction forces and naturally increases the effectiveness of the pulling or jetting.

The weight of the cable affects the pulling performance: the pulling efficiency is even greater because the cable is light. The pulling force can also be reduced. Outside, the cable is designed to offer a maximum allowable tension (MAT). The smaller the MAT, the less reinforcement the cable will need, meaning it will be smaller and lighter.

Overhead cables

For overhead infrastructures, the diameter of the cable is a priority because it is directly related to its climatic performance (maximum wind speed, thickness of ice, etc.). The smaller the diameter of the cable, the less surface area is exposed to the elements : the wind resistance force is reduced, as is the impact of the weight of snow or ice. In addition, a lighter cable means a reduction in tension when it is being installed.

For an overhead cable, a high MAT is synonymous with fibre protection at elongation. Nevertheless, the higher the MAT, the more reinforcement it will have, meaning the cable will be bigger and therefore heavier. Also, the performance of an overhead cable is assessed in terms of its MAT/weight ratio, which must be greater than 2daN/kg/km.

More about optical fibre elongation in overhead cable, in this article.

Optimisation of the overall cost of ownership

To summarise the previously studied characteristics, the main advantage of Loose Tube technology is its CAPEX (investment cost): it is the cheapest solution to purchase. However, the Compact Tube offers a much lower OPEX (installation and operating cost) than the Loose Tube. Ultimately, a calculation of the total cost of ownership (TCO), including all costs, investment, installation and operation, demonstrates the economic advantage of the Compact Tube.

Compact Tube® is a more versatile technology which is preferred by installation and commissioning teams and which delivers excellent results in all fields.

Comparative summary of the different characteristics of the technologies studied

|

Characteristics |

Benefits |

Loose Tube |

Micro-Loose Tube |

ACOME Compact Tube® |

|

Access to the fibre |

Easy, secure and fast deployment |

«««¶¶ |

«««¶¶ |

««««« |

|

Impact of the jelly |

Time saved when deploying |

«¶¶¶¶ |

«««¶¶ |

««««¶ |

|

Safety in terms of kink effect |

Avoids time lost due to cable replacement |

«¶¶¶¶ |

«««¶¶ |

««««« |

|

Bending radius |

Less space required |

«¶¶¶¶ |

«««¶¶ |

««««« |

| Connectivity/assembly |

Less space required |

«¶¶¶¶ |

«««¶¶ |

««««« |

| Size / diameter |

More capacity for fibres |

««¶¶¶ |

«««¶¶ |

««««¶ |

|

Weight |

Time saved when deploying |

«¶¶¶¶ |

«««¶¶ |

««««¶ |

|

Use in overhead cables |

Greater distance between poles |

«¶¶¶¶ |

««««¶ |

««««« |

|

Use in cables in ducts |

Time saved when deploying |

«««¶¶ |

««««¶ |

««««¶ |

|

Use in micro-ducts (jetting) |

Greater distance in ducts |

«¶¶¶¶ |

««««« |

««««¶ |

|

Midspan access |

Time saved when deploying |

«¶¶¶¶ |

«««¶¶ |

««««« |

|

CAPEX (investment cost) |

Economies d’investissement |

««««« |

«««¶¶ |

«««¶¶ |

|

OPEX (operating cost) |

TCO optimisation |

«¶¶¶¶ |

«««¶¶ |

««««« |